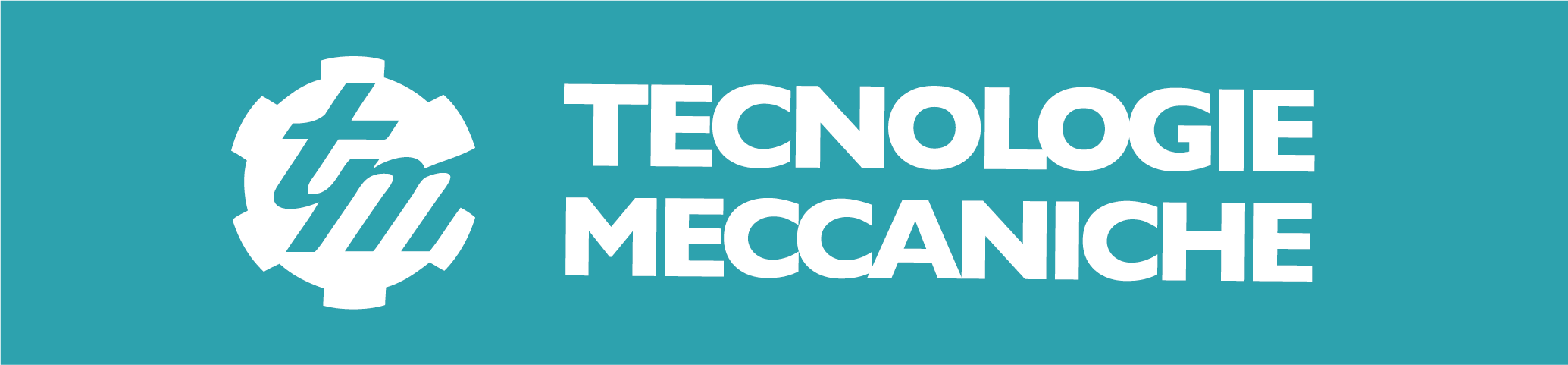

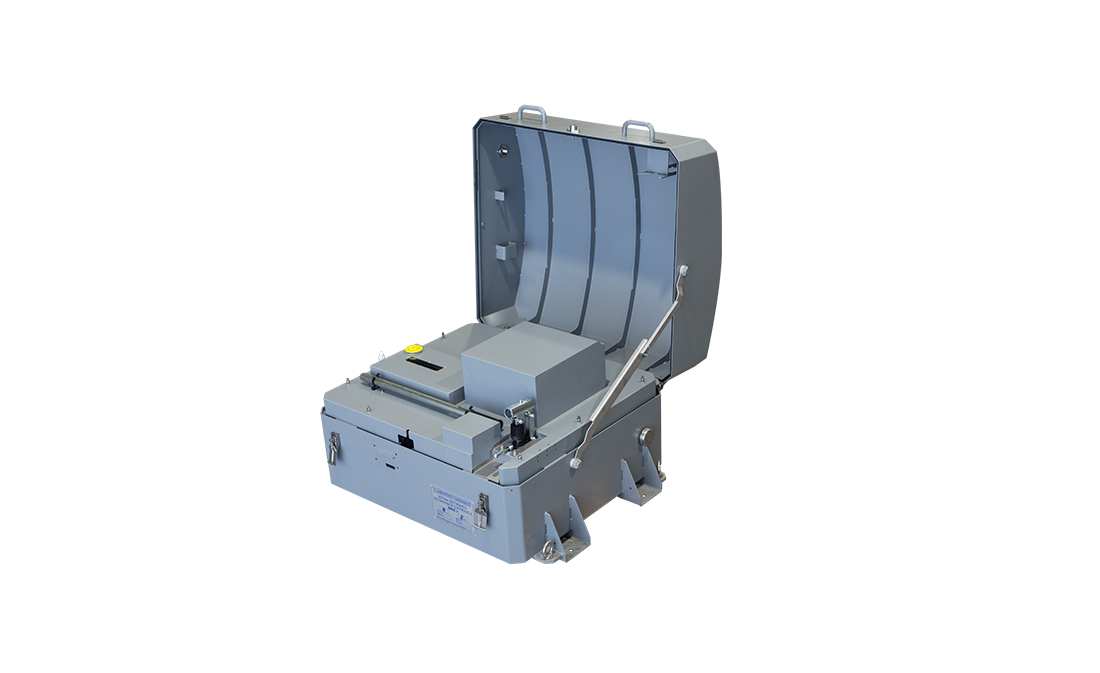

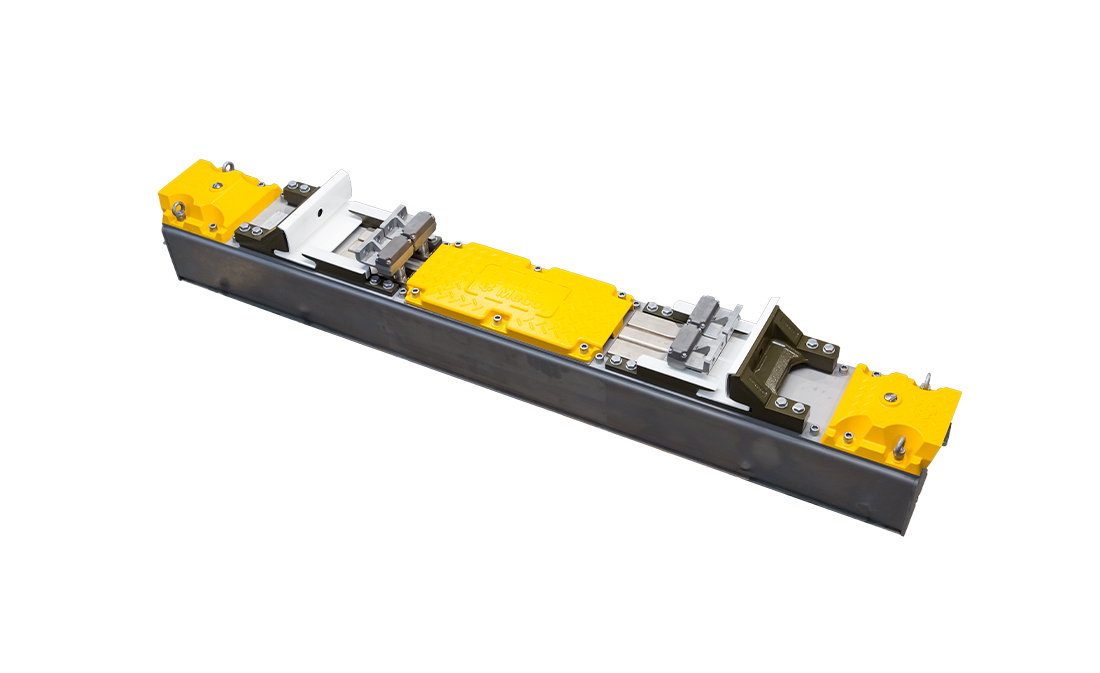

The acronym SECC (Sistema Elettronico di Comando e Controllo) identifies a family of hydraulic switching systems for switchgear designed and produced by Tecnologie Meccaniche.

The SECC control systems are designed to operate alongside the hydraulic actuators present in the switchboards of the high speed lines (HS) and to replace the existing control units SAV2 (replaced by SECC TM54) and CMI3 (replaced by SECC-PLUS TM73).

The systems designed by Tecnologie Meccaniche allow to replace the old control units without making any electrical changes to the system. In fact, the Electronic Command and Control System for Hydraulic Switching is designed to simulate the behavior of the old systems, so that the signaling system does not perceive any difference in behavior at the electrical level; moreover, the pressures used and the hydraulic interfaces are fully compatible with the hydraulic actuators present on the line.

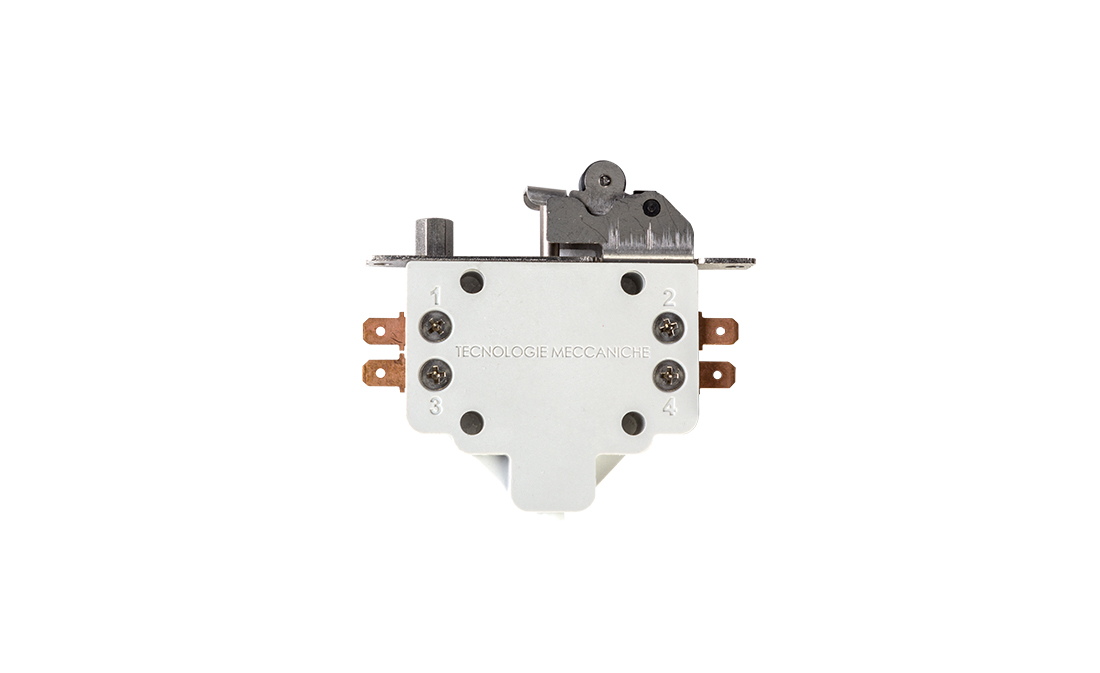

The innovative element is the use of two central processing units (one for the switch frame and the other for the mobile core), realized in 2oo2 microcontroller architecture in diversity, equipped with a rich network of hydraulic sensors, which control the movement of the switch with SIL4 safety level.

The SECC systems, thanks to the introduction of electronics and the improvement of the motion control algorithms, make it possible to detect obstacles between the needle and the switch of more than 7 mm with SIL4 safety level. The on-board electronics and the supplied diagnostic software allow early detection of a number of typical breaker degradation patterns, enabling effective predictive diagnostics and optimization of the time and method of intervention on the switch.

SECC systems are compatible with RFI system schemes and guarantee a SIL4 safety level in compliance with CENELEC 50126 and 50219 standards.